GATE VALVE MANUFACTURER IN AHMEDABAD, GUJARAT, INDIA.

| SUITABLE FOR | ||||

| STEAM | WATER | OIL | AIR | GASES |

| • | • | • | ||

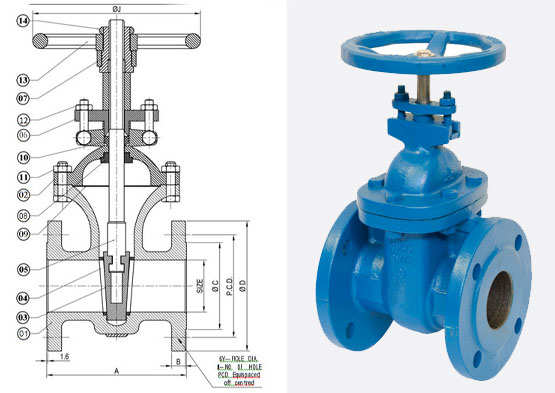

| SR. NO. | PARTS NAME | MATERIAL | QTY. |

|---|---|---|---|

| 01. | BODY | C.S. ASTMA216Gr. WCB | 1 |

| 02. | BONNET | C.S.ASTMA216Gr.WCB | 1 |

| 03. | WEDGE | C.S. WITH 13 % CRORM FACING | 1 |

| 04. | SEAT RING | S.S. 13% CR. A216GR. WCB | 2 |

| OS. | STEM | AISI410(13%CR) | 1 |

| 06. | GLAND | C.S. ASTM A 216 GR. WCB | 1 |

| 07. | YOKE SLEEVE | GM / SS AISI 304 | 1 |

| 08. | BONNET BUSH | SSAISI410 | 1 |

| 09. | GASKET | SPRIAL WOUND METALIC | 1 |

| 10. | GLAND PACKING | GRAPHOIL ASBESTOS | — |

| 11. | BONNET STUD & NUT | ASTM A 193 Gr. B7 / ASTM A 194 Gr. 2H | - |

| 12. | EYE BOLT 8, NUT | CARBON STEEL | 2 SET |

| 13. | HAND WHEEL | CAST IRON / CAST STEEL | 1 |

| 14. | HAND WHEEL NUT | CARBON STEEL | 1 |

| Size | CLASS-150 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| IN. | MM | A | B | 0C | 0D | 0M | N | PCD | 0J |

| 1" | 25 | 127.0 | 11.0 | 51 | 108.0 | 16 | 4 | 79.2 | 123 |

| 1.1/2" | 40 | 165.1 | 14.2 | 73 | 127.0 | 16 | 4 | 98.5 | 152 |

| 2" | 50 | 177.8 | 15.7 | 92 | 152.0 | 19 | 4 | 120.6 | 203 |

| 2.1/2" | 65 | 190.5 | 17.5 | 105 | 178.0 | 19 | 4 | 139.7 | 203 |

| 3" | 80 | 203.2 | 19.0 | 127 | 190.5 | 19 | 4 | 152.4 | 254 |

| 4" | 100 | 228.6 | 24.0 | 157 | 229.0 | 19 | 8 | 190.5 | 305 |

| 5" | 125 | 254.0 | 24.0 | 186 | 254.0 | 22 | 8 | 215.9 | 305 |

| 6" | 150 | 266.7 | 25.0 | 216 | 279.0 | 22 | 8 | 241.3 | 356 |

| 8" | 200 | 292.1 | 28.5 | 270 | 343.0 | 22 | 8 | 298.4 | 356 |

| 10" | 250 | 330.2 | 30.0 | 324 | 406.0 | 25 | 12 | 362.0 | 406 |

| 12" | 300 | 355.6 | 32.0 | 381 | 483.0 | 25 | 12 | 431.8 | 457 |

| 14" | 350 | 381.0 | 35.0 | 413 | 534.0 | 28 | 12 | 476.2 | 508 |

| 16" | 400 | 406.4 | 36.5 | 470 | 597.0 | 28 | 16 | 539.7 | 508 |

| 18" | 458 | ||||||||

| 20" | 508 | ||||||||

| Size | CLASS-300 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| IN. | MM | A | B | 0C | 0D | 0M | N | PCD | 0J |

| 1.1/2" | 40 | 190.5 | 20.5 | 73 | 155.4 | 22 | 4 | 114.3 | 152 |

| 2" | 50 | 215.9 | 22.0 | 92 | 165.0 | 19 | 8 | 127.0 | 203 |

| 2.1/2" | 65 | 241.3 | 25.0 | 105 | 190.5 | 22 | 8 | 149.3 | 203 |

| 3" | 80 | 282.5 | 28.5 | 127 | 209.5 | 22 | 8 | 168.1 | 254 |

| 4" | 100 | 304.8 | 32.0 | 157 | 254.0 | 22 | 8 | 200.1 | 305 |

| 5" | 125 | 381.0 | 35.0 | 186 | 279.4 | 22 | 8 | 234.9 | 356 |

| 6" | 150 | 403.2 | 36.5 | 216 | 317.5 | 22 | 12 | 269.7 | 356 |

| 8" | 200 | 419.1 | 41.0 | 270 | 381.0 | 25 | 12 | 330.2 | 406 |

| 10" | 250 | 457.2 | 48.0 | 324 | 444.5 | 29 | 16 | 387.3 | 457 |

| 12" | 300 | 501.6 | 51.0 | 381 | 520.7 | 32 | 16 | 450.8 | 508 |

| 14" | 350 | 762.0 | 54.0 | 413 | 584.2 | 32 | 20 | 514.3 | 508 |

| 16" | 400 | 838.2 | 57.0 | 470 | 647.7 | 35 | 20 | 571.5 | 508 |

| 18" | |||||||||

| 20" | |||||||||

| TECHNICAL DATA | |

| DESIGN & MANUFACTURING STD | BS-1414/API600 |

| TESTING & INSPECTION STD. | API 598 |

| END CONNECTIONS : | FLANGED AS PER ANSI B-16.5 |

| SHELL WALL THICKNESS | ANSI B 16.34 |

| FACE TO FACE : | AS PER ANSI/B 16.10 |

| PRIMARY SERVICE RATING & TEST PRESSURE | ||||

| CLASS | WORKING PRESSURE | TEMP | HYD.TEST BODY PRESSURE BODY SEAT |

|

| 150 | 150 PSIG | 500° F | 425 PSIG | 300 PSIG |

| AIR TEST-S | EAT 80 PSIG ±10 PSIG | |||